The car shredder is also called metal shredder. The car shredder series products are mainly di

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

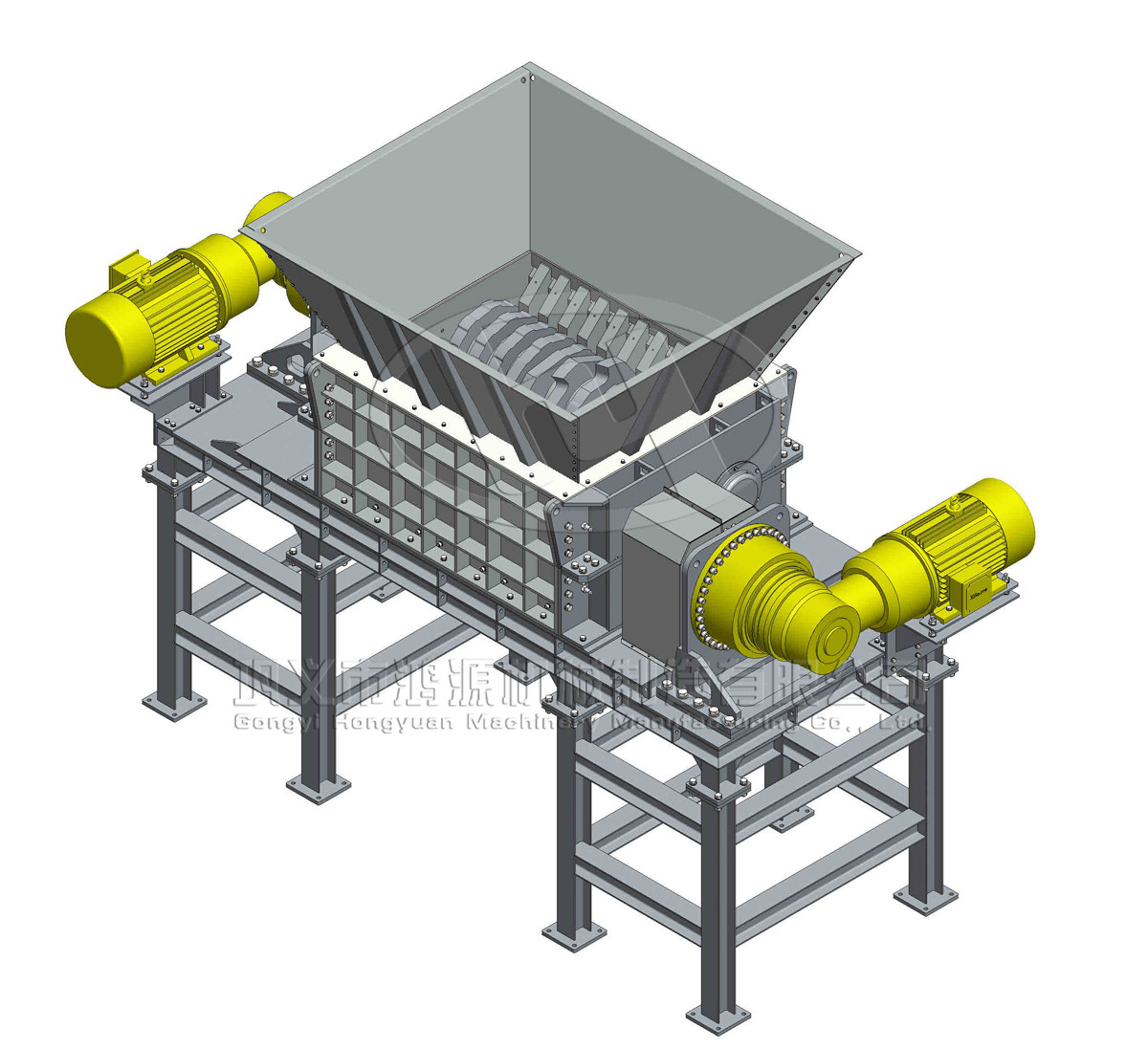

The car shredder is also called metal shredder. The car shredder series products are mainly divided into two-axis metal shredder and four-axis shredder, which can meet the user’s processing of large, medium and small scrap crushing. In the applicable characteristics of the equipment, the car shredder can be used to replace the gantry scissors for the coarse crushing operation of the car shell. Compared with the original car shearing and crushing process, the whole car shredding and crushing production line has more complete automatic control technology. The entire production line needs to be lower in manual investment, and the output can be increased by more than 28%, which is more suitable for the mass-produced waste car crushing treatment of the automobile dismantling center.

working principle

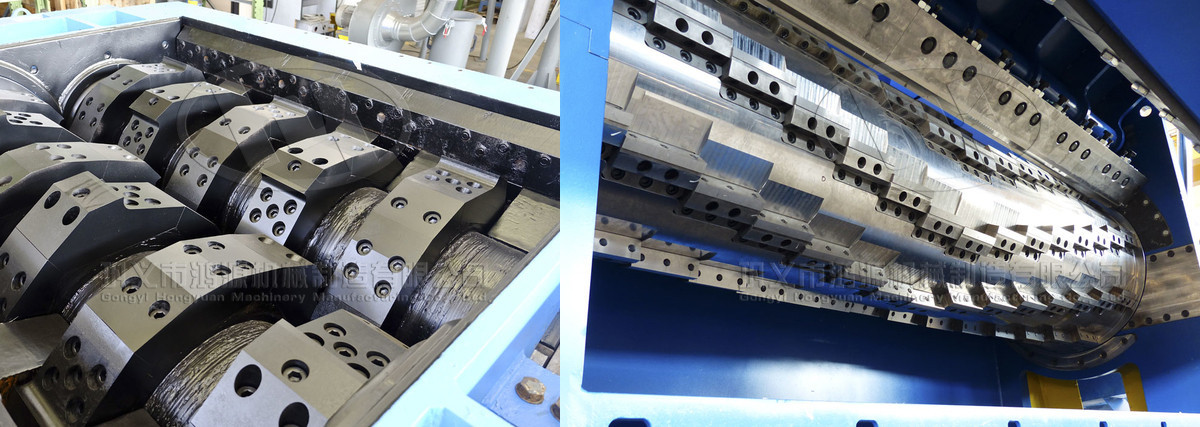

During the working process, the power is stably transmitted to the main shaft through the reducer connected to the motor, and the scrap metal entering the shredder cavity is clamped by the shredder blade fixed on the main shaft under the traction of the main shaft. During the continuous pressing process of the blade card position, the material is wound into the two-axis gap, and the material is crushed by the double-axis tearing action. After the crushed material, the material is usually stripped or flake-shaped and filtered by the bottom of the device and transported through the conveyor belt. The material is processed centrally for other equipment or collected directly. Due to the low-speed and high-torque design, the machine has outstanding performance in the process of scrapping the scrap steel crusher. If the crushed crushed coarse material is finely powdered, the belt can be loaded at the tail. The machine completes the whole fine crushing process through the connection with the scrap crusher, and can realize the classification and recovery of metal, plastic and glass in the scrap through the related equipment.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.