The four-axis shredder is a multi-axis auxiliary large-volume material crusher produced by Hon

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

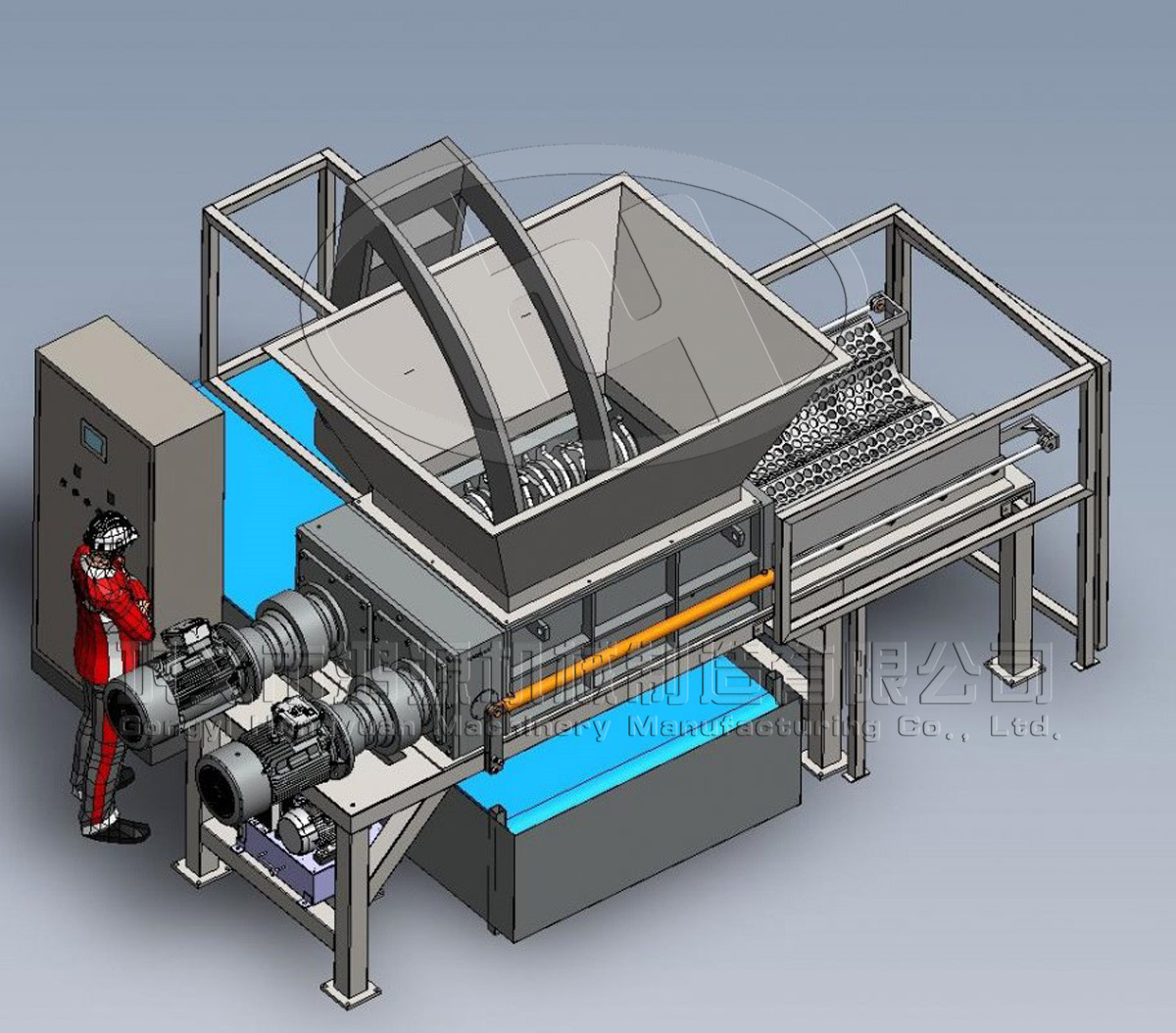

The four-axis shredder is a multi-axis auxiliary large-volume material crusher produced by Hongyuan Machinery. It can be used in the crushing of various refrigerators, TV sets, petrol cans and diesel drums. The crusher has a larger crushing ratio than the double-shaft shredder, and the equipment investment cost is lower, which is more suitable for the crushing and processing of batch thin materials. The machine adopts four sets of shredders in the composition of the machine, and realizes the primary auxiliary crushing and auxiliary feeding of wood, plastic, metal, garbage and other materials through the cooperation between the shafts, and then through the bottom two shafts and the off-axis shredding operation. Hongyuan four-axis shredder is a multi-axis linkage control device, which can realize synchronous continuous machining between shafts in terms of technical advantages.

Features

1: Screen can be customized according to user requirements. Installation and disassembly are hydraulic control.

2: Long tool life, high utilization, and can be maintained multiple times

3: Control system: PLC control system, easy to operate and maintain

4: The main knife standard is the double claw material for the alloy tool steel auxiliary knife standard for the four claw material

5: The bearings, motors and reducers used in this machine are all well-known brands in China, and the main electrical components are Schneider, Mitsubishi, ABB and other brands.

6: The design of the machine body is reasonable, and the equipment is welded or cast with high wear-resistant steel to make the operation more stable.

7: Spindle synchronous design can effectively avoid equipment chaos.

Principle mechanism

The four-axis shredder adopts four sets of blades with rotors under the fixed action of the body to drive the main shaft to rotate. When the material enters the machine cavity, the bulk material is first fixed by the upper two sets of rotors. The coarsely crushed material is forcibly shredded by the bottom rotor after being fixedly pulled, and the material broken by the toothed disc processing is directly discharged through the bottom to discharge the machine cavity. In the equipment circuit control system, Hongyuan mechanical four-axis shredder adopts Mitsubishi plc programmable controller as the main controller, and controls the rapid closing of the motor and hydraulic system through the AC contactor and electromagnetic reversing valve, and integrates the synchronous adjustment. The speed system can effectively guarantee the synchronization of the four axes, which lays a foundation for high efficiency and high material feeding performance during the operation of the equipment.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.