The multi-function shredder is called the multi-function shredder. It is a kind of material crus

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

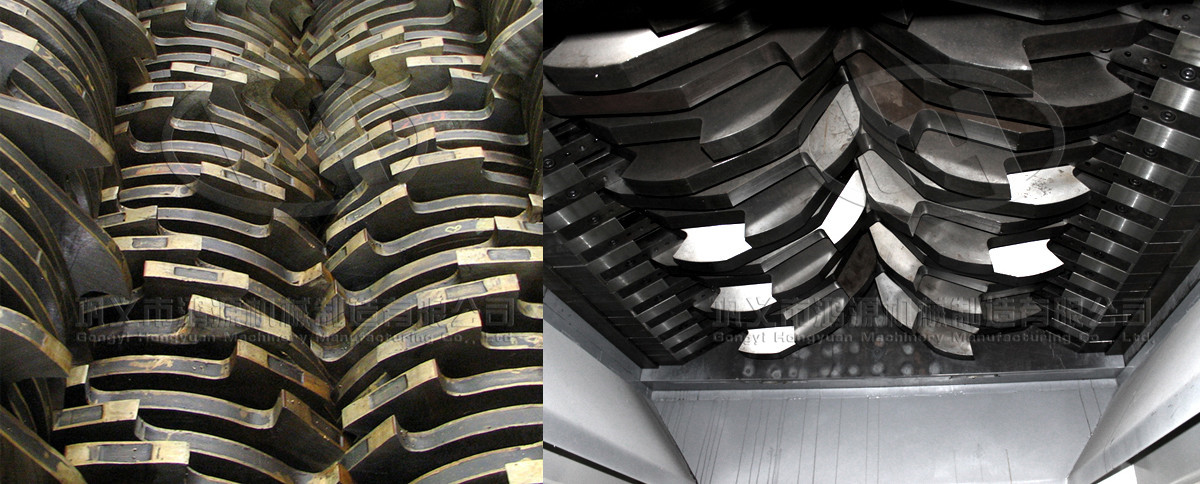

The multi-function shredder is called the multi-function shredder. It is a kind of material crushing processing equipment suitable for the domestic market, which is improved by the R&D department of our company after the absorption of foreign advanced experience. This machine is mainly used in the crushing of waste plastics, waste rubber, wood, paint buckets, waste appliance casings (plastic shells, metal shells), used circuit boards (circuit boards), used cable wires and other large-volume wastes. Compared with other pulverizer equipment, the multi-function shredder belongs to the slow high-torque crushing equipment. The processing materials are mainly concentrated on the crushing of metal and plastic components and the crushing of large hard materials. The multi-functional shredder is mainly used in equipment construction. It consists of a shredder blade set, a carrying case, a box bracket, a feeding system, a power system, and an electrical control system. The machine’s unique power protection mechanism can effectively prevent equipment overload caused by crushing large scrap metal. damage.

working principle

Multi-function shredder This machine will transfer the power to the main shaft through the reducer connected to the motor during the working process. Under the traction of the main shaft, the shredder blade fixed on the main shaft will enter the metal shredder machine cavity. The scrap metal is clamped, and the material is wound into the two-axis gap during the continuous pressing process of the blade card position, and the material is crushed by the double-axis tearing action, and the crushed material usually presents a strip or a sheet shape. The bottom of the equipment is filtered out and transported through the conveyor belt to the other equipment for centralized processing or direct collection.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.