In recent years, with the rapid development of the rubber manufacturing industry, the source rub

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

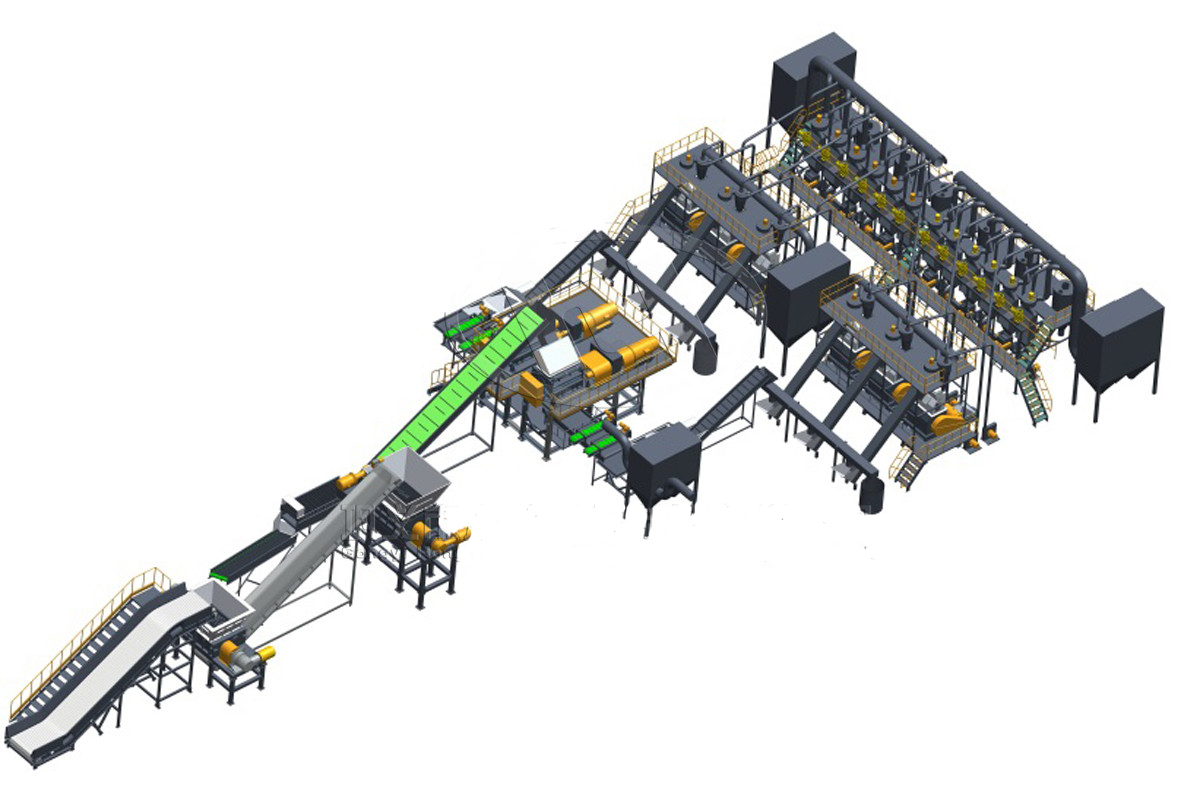

In recent years, with the rapid development of the rubber manufacturing industry, the source rubber is becoming increasingly scarce. How to effectively use the waste rubber has become a problem to be solved by humans all over the world, and some rely on the purchase of expensive or high-power and low-efficiency equipment. The investment cost is too high, and some use the original sawing and processing method to crush and reuse the waste rubber. However, due to the extremely low production efficiency and the inability to achieve the corresponding economic value, it has not been promoted and applied. The high-efficiency rubber shredder produced by WALLE Machinery through the existing manufacturing process is a high-quality equipment for the recycling of waste rubber. The machine and the original used tire shredder are a kind of equipment, all of which are high at low speed. Torque is developed and designed as the overall production and processing concept, so that the major rubber molding processing units and waste rubber recycling processing units continue to obtain high-quality production equipment into the rubber processing industry.

WALLE Machinery can provide you with single-axis rubber shredder, double-shaft rubber shredder and four-axis rubber shredder at high quality. The processing range is shredded from small tires with small rubber trim, after blade replacement. For scrap metal, plastic, wood and other waste materials can be broken production.

In the working principle, the waste rubber shredder adopts the single-axis, double-shaft or four-axis as the crushing mechanism of the equipment to form the broken angle with the fixed knife, and the change of the angle between the shafts and the shredding after the speed change of the reducer is driven by the motor. The clamping pressure of the machine blade presses the material into the angle of the shaft, and the radial pressure is generated under the action of the decreasing angle of the shaft. The material is torn by the large pressure under the action of the radial pressure and the blade tearing. The fission forms a small piece of granules, and the screening effect of the sieve passing through the bottom of the rubber shredder is sized. The particles that are not sized by the bottom screen of the shredder are again sent to the angle between the shaft and the fixed knife. Broken processing. In the whole crushing process, we usually use 50*50 round mesh sieve as the rough selection structure. After the rubber block that meets the required size (50×50), it can be processed into 6-12mm rubber pellets after being discharged into the rubber crusher. The rubber particles can also be further milled using a rubber milling device.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.