The shredder is also called double-shaft crusher and shear shredder. It is widely used in wast

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

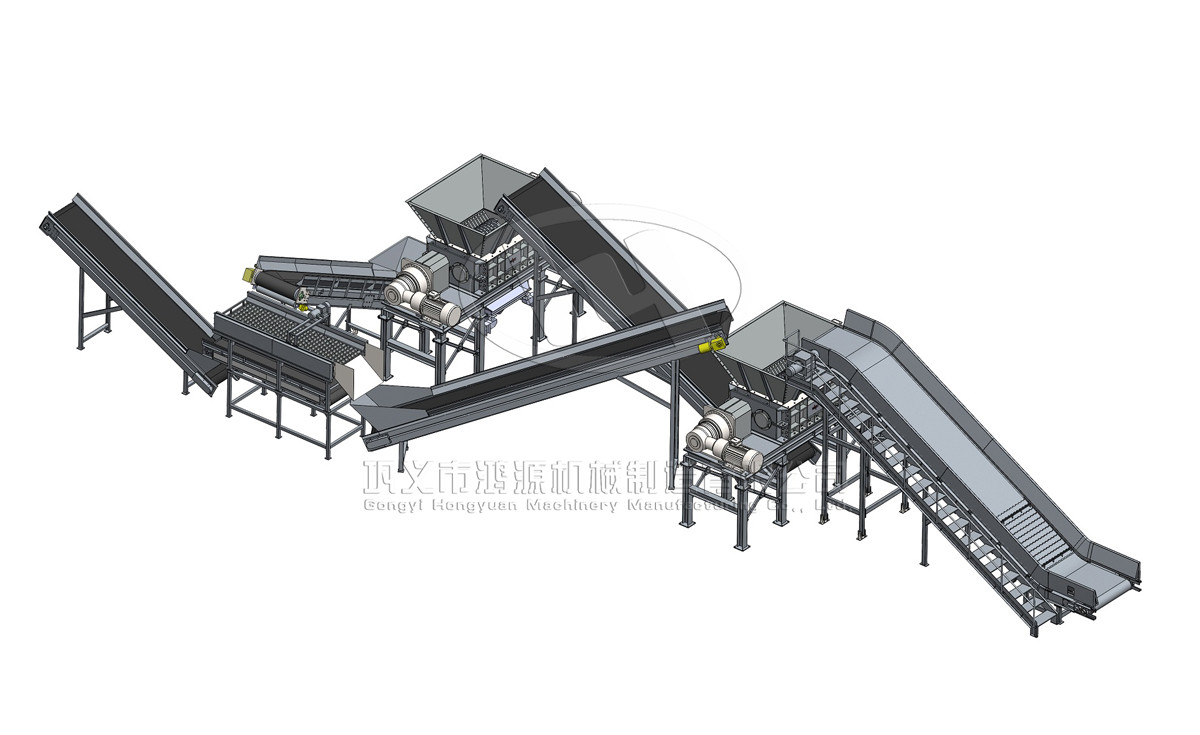

The shredder is also called double-shaft crusher and shear shredder. It is widely used in waste plastics, waste rubber, wood, paint buckets, discarded household appliances (plastic shells, metal shells), and waste circuit boards (circuit boards). ), waste cable and other large-volume waste crushing processing, compared to other crusher equipment, the double-shaft shredder is a slow high-torque crushing equipment, mainly on the processing materials to break the metal and plastic components and large hard The crushing and processing of materials, Hongyuan Machinery Double Shaft Shredder is a kind of material crushing processing equipment suitable for the domestic market, which is improved according to the specific development needs of the market after absorbing foreign advanced experience.

working principle

The shredder uses two rotors with a shredder blade to rotate relative to each other in the machine cavity to squeeze the material entering the machine cavity by the principle of shrinking the angle between the two axes. The special design of the blade enters the angle of the two axes. The material after being fixed by the edge of the blade further creates conditions for the contraction of the angle. After the material is forced to reach the yield strength of the material, the material starts to break between the blades, thereby completing the shredding effect.

Features

1. The shredder is suitable for processing and crushing wood, metal, plastic and other materials.

2. Compared with single-axis crusher, it has a wider application range.

3. Designing a unique rotary knife in terms of thickness, shape and arrangement order, with strong shearing force and sharp edge, which can be crushed with high efficiency.

4, the special structure of the extra-thick sheet precision processing frame, the powerful rotating shaft of the large-angle hexagonal column, the large diameter is firmly put into the hopper, so you can invest in large-scale raw materials with confidence.

5. The cutter is made of special alloy steel and is durable.

6, low speed operation, low noise, less dust.

7, programmable control, multi-stage speed regulation is suitable for the crushing of different materials.

8. The discharge particle size is uniform.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.