The can crusher is also called the can crusher. This machine is a kind of high-efficiency crushing

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

The

can crusher is also called the can crusher. This machine is a kind of

high-efficiency crushing equipment developed by our company’s technical

experts in combination with the actual demand of the new can crushing

market. The crushed cans are round spherical particles and the materials

in the crushing process. An

effective purification treatment is obtained, which provides high

quality conditions for reducing the phosphorus content in the material

and increasing the material density. In

the application, the can crusher is mainly applied to the processing of

scrap metal in the waste metal recycling site. The processed material

can be directly used in converter steelmaking as the charge. In

the structure principle, the cans are crushed, impacted and ground by

the internal hammer of the machine cavity during the use of the crusher.

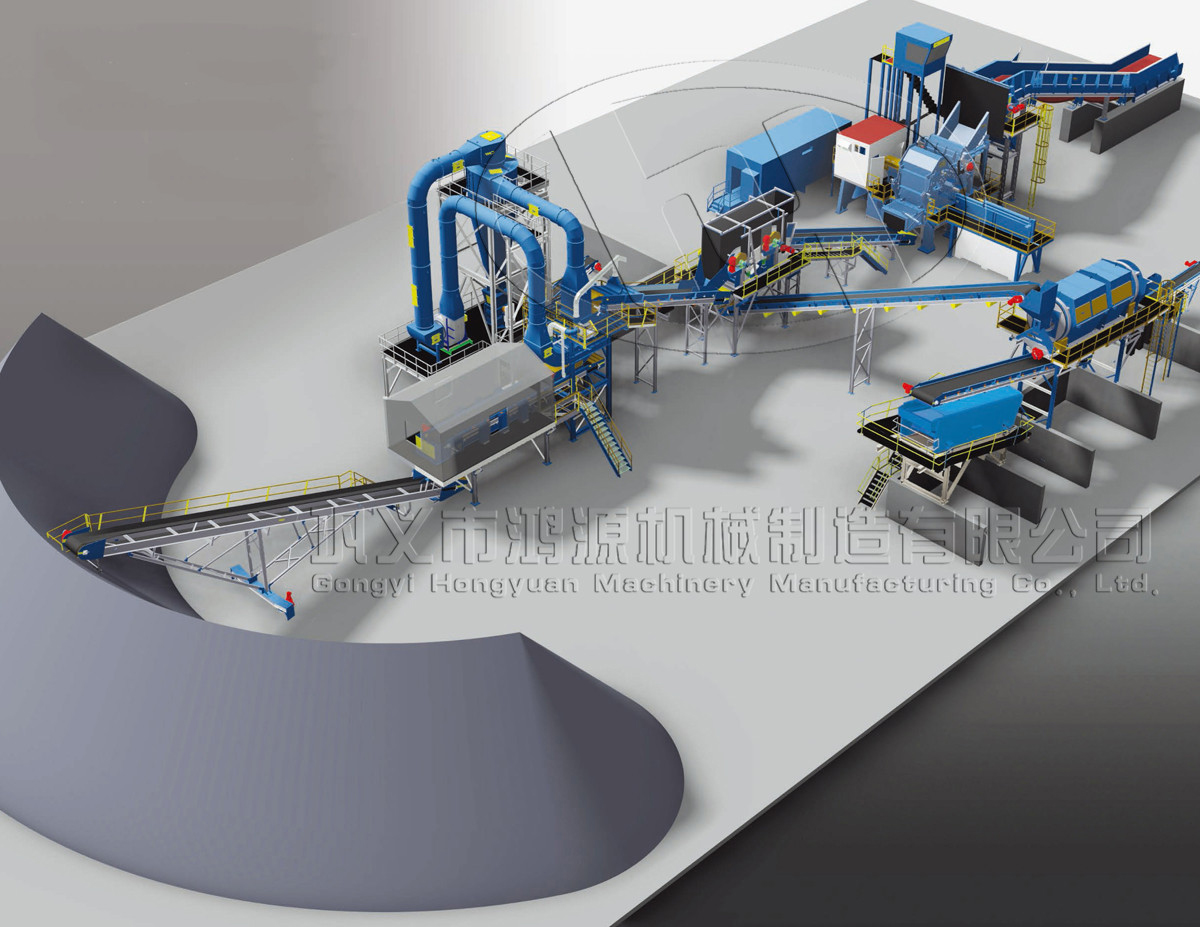

The machine is mainly equipped with: main machine, feeding, discharging

and magnetic separation. It consists of a machine, a dust removal system and an electronic control unit. In

the application effect of the equipment, the can crusher can crush all

kinds of waste cans, cans, waste metal, paint buckets and other light

and thin metals, and realize the process of scrapping and recycling of

waste cans to reduce the cost of transportation and refining of

materials. .

Structural principle

The

basic principle of the motor driven by the motor of the can crusher is

that under the drive of the high-speed and high-torque motor, the

crushed material can be fully and effectively broken in the crushing

cavity, and the object to be crushed is torn into a crushed product

conforming to the specification. The

crushed material is separated from the metal and non-metal by the air

cyclone sorting system, and the whole system is equipped with a dust

removing device to reduce the dust pollution hazard generated during the

production process. The

equipment mainly has the advantages of high output, low energy

consumption, high efficiency, uniform discharge and fineness. Moreover,

when the device is used, the noise is low, pollution-free, and the

operation is simple and the maintenance is convenient.

| model | power | Application range | Rotating speed | Processing capacity(t/h) | Dimensions(mm) | weight(t) |

| 800PSJ-C | 37-55 | Cans, thin iron, light metal | 1250 | 0.7-1 | 3800*1600*1800 | 3.2 |

| 1000PSJ-C | 45-75 | Small metal packing, cans, scrap metal | 1250 | 0.8-1.5 | 2560*1800*2200 | 7.6 |

| 1300PSJ-C | 90-150 | Scrap metal blocks such as bicycles and motorcycles | 860 | 2-4 | 4000*3500*3200 | 11.5-26 |

| 1600PSJ-C | 200-280 | Scrap metal parts such as automobile cutting parts and paint buckets | 750 | 4-6 | 4800*4000*3800 | 16.6-35 |

| 1800PSJ-C | 220-450 | Scrapped large scrap metal blocks | 650 | 6-10 | 4800*4100*4000 | 32-48 |

| 2000PSJ-C | 315-630 | Scrapped large scrap metal blocks | 650 | 8-12 | 5000*4500*4300 | 35-65 |

| 2200PSJ-C | 500-900 | Scrapped large scrap metal blocks | 650 | 15-20 | 5000*4500*4300 | 35-65 |

| 2400PSJ-C | 1250-2250 | Large metal packing, car shell | 650 | 20-45 | 6300*4800*4500 | 85-120 |

| 2800PSJ-C | 1600-3300 | Various scrap metal | 650 | 70-100 | 6400*5200*4800 | 145-230 |

| 3000PSJ-C | 3300-4400 | Various scrap metal | 650 | 110-140 | 8500*7200*5500 | 280-760 |

Copyright © 2099 Walle Recycle All Rights Reserved.