The paint bucket pulverizer is a kind of hitting crushing metal equipment. It is mainly used f

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

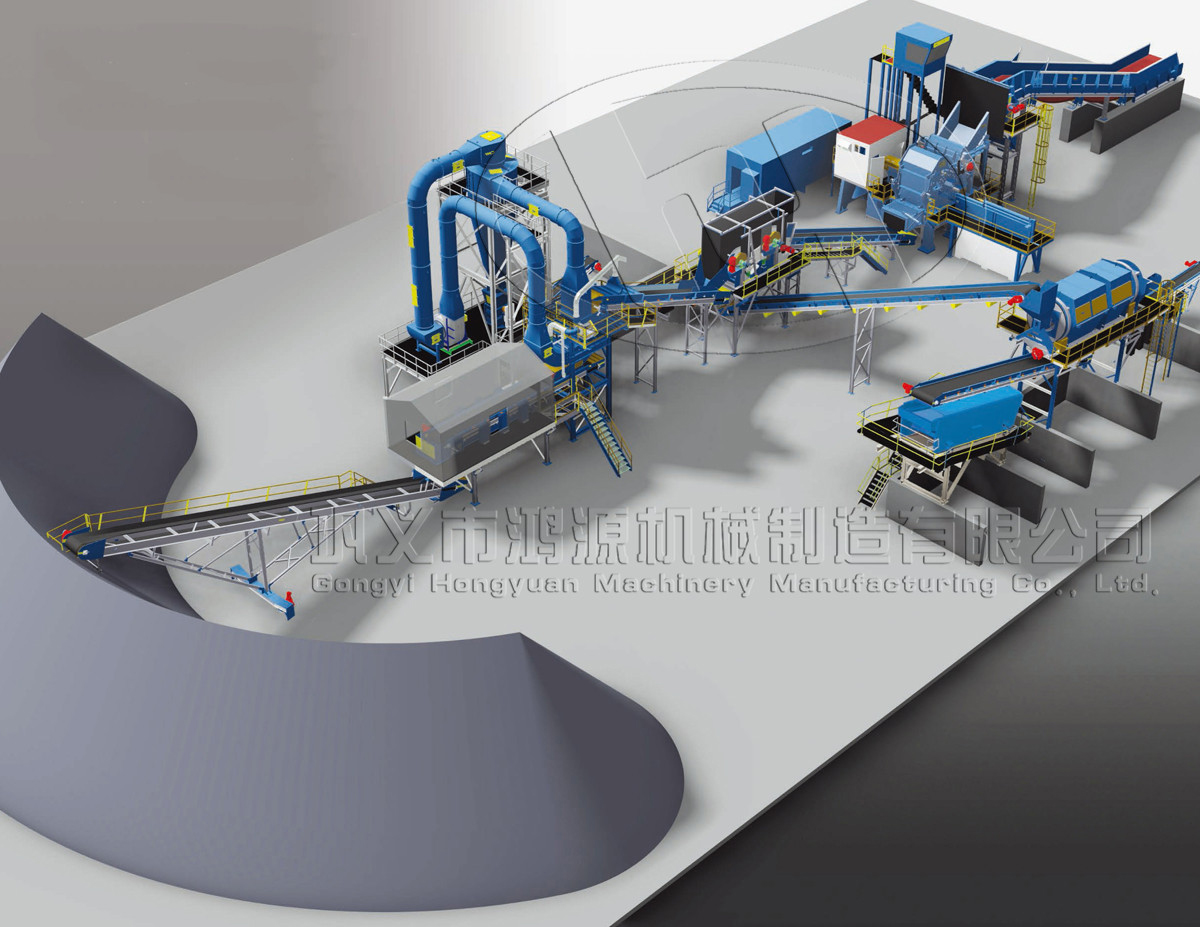

The paint bucket pulverizer is a kind of hitting crushing metal equipment. It is mainly used for crushing and processing waste metal barrels such as paint buckets, gasoline drums, diesel drums and oil drums. The paint bucket crusher mainly has equipment composition. : Crusher main machine, feeding conveyor, discharge conveyor, centralized dust collector, magnetic separator, etc. to achieve the purity of waste paint bucket. The paint bucket crushed by the machine has the advantages of low metallurgical cost, low transportation cost, energy saving and environmental protection. The paint bucket crusher is also a new type of high efficiency, energy saving and environmentally friendly metal crusher. The machine has the characteristics of flexible operation, tight structure and large output.

Structural principle

In the work flow, the paint bucket crusher is sent to the equipment for forced feeding and crushing through the paint bucket of the feeding conveyor, and the metal briquetting is subjected to primary crushing by crushing of the pressing roller and the coarse crushing shaft, after primary crushing. The paint bucket enters the main cavity of the device. Under the drive of the high-speed and high-torque motor, the hammer on the main rotor alternately hits the paint bucket entering the main cavity through the space between the liner and the hammer, and the crushed paint bucket is in the crushing chamber. A sufficient and effective fine crush can be obtained from the screen and flow down from the screen. The crushed material passes through the air cyclone sorting system to separate the paint, rust and waste plastic of the paint bucket, and the material discharged at the bottom of the equipment is transported to the collecting point through the conveying equipment, and the non-magnetic material contained in the material in the process Under the action of the magnetic separator, the production line is sorted and discharged to the non-magnetic material pile. In addition, the entire system is equipped with a dust removal device to reduce the dust pollution hazard generated during the production process. The equipment mainly has the advantages of high output, low energy consumption, high efficiency, uniform discharge and fineness.

| model | power | Application range | Rotating speed | Processing capacity(t/h) | Dimensions(mm) | weight(t) |

| 800PSJ-C | 37-55 | Cans, thin iron, light metal | 1250 | 0.7-1 | 3800*1600*1800 | 3.2 |

| 1000PSJ-C | 45-75 | Small metal packing, cans, scrap metal | 1250 | 0.8-1.5 | 2560*1800*2200 | 7.6 |

| 1300PSJ-C | 90-150 | Scrap metal blocks such as bicycles and motorcycles | 860 | 2-4 | 4000*3500*3200 | 11.5-26 |

| 1600PSJ-C | 200-280 | Scrap metal parts such as automobile cutting parts and paint buckets | 750 | 4-6 | 4800*4000*3800 | 16.6-35 |

| 1800PSJ-C | 220-450 | Scrapped large scrap metal blocks | 650 | 6-10 | 4800*4100*4000 | 32-48 |

| 2000PSJ-C | 315-630 | Scrapped large scrap metal blocks | 650 | 8-12 | 5000*4500*4300 | 35-65 |

| 2200PSJ-C | 500-900 | Scrapped large scrap metal blocks | 650 | 15-20 | 5000*4500*4300 | 35-65 |

| 2400PSJ-C | 1250-2250 | Large metal packing, car shell | 650 | 20-45 | 6300*4800*4500 | 85-120 |

| 2800PSJ-C | 1600-3300 | Various scrap metal | 650 | 70-100 | 6400*5200*4800 | 145-230 |

| 3000PSJ-C | 3300-4400 | Various scrap metal | 650 | 110-140 | 8500*7200*5500 | 280-760 |

Copyright © 2099 Walle Recycle All Rights Reserved.