The car crusher is a new generation of products developed by our company’s R&D personnel in

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

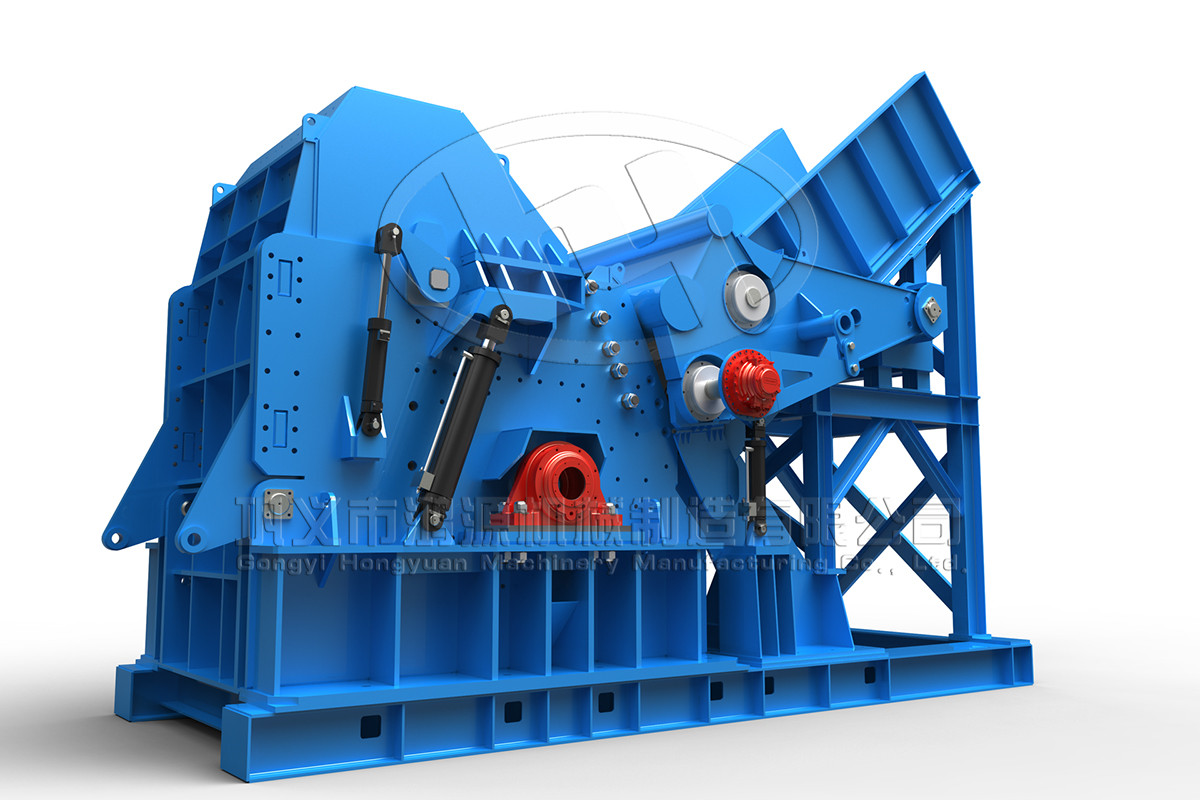

The car crusher is a new generation of products developed by our company’s R&D personnel in combination with international advanced technology. It can be used to crush all kinds of scrapped car compartments to realize the intelligent automatic crushing processing of scrapped cars, in order to reduce the difficulty of manual operation and low efficiency. The scrapped car crusher is a hitting type car crushing equipment, and the scrapped after the machine is scrapped. The automobile is granular metal particles, which are crushed by the hammering action inside the equipment. During the fine crushing process, the metal material is elastically deformed and gradually shrinks into a spherical shape, thereby realizing the separation of the metal surface paint and oil stain to realize the recovery of high-purity metal. . After the equipment is equipped with centralized dust removal and sorting equipment, the wires, aluminum, rubber and plastic in the used car can be effectively sorted. The application of the car crusher not only increases the production capacity and crushing efficiency, but also expands the scope of application.

working principle

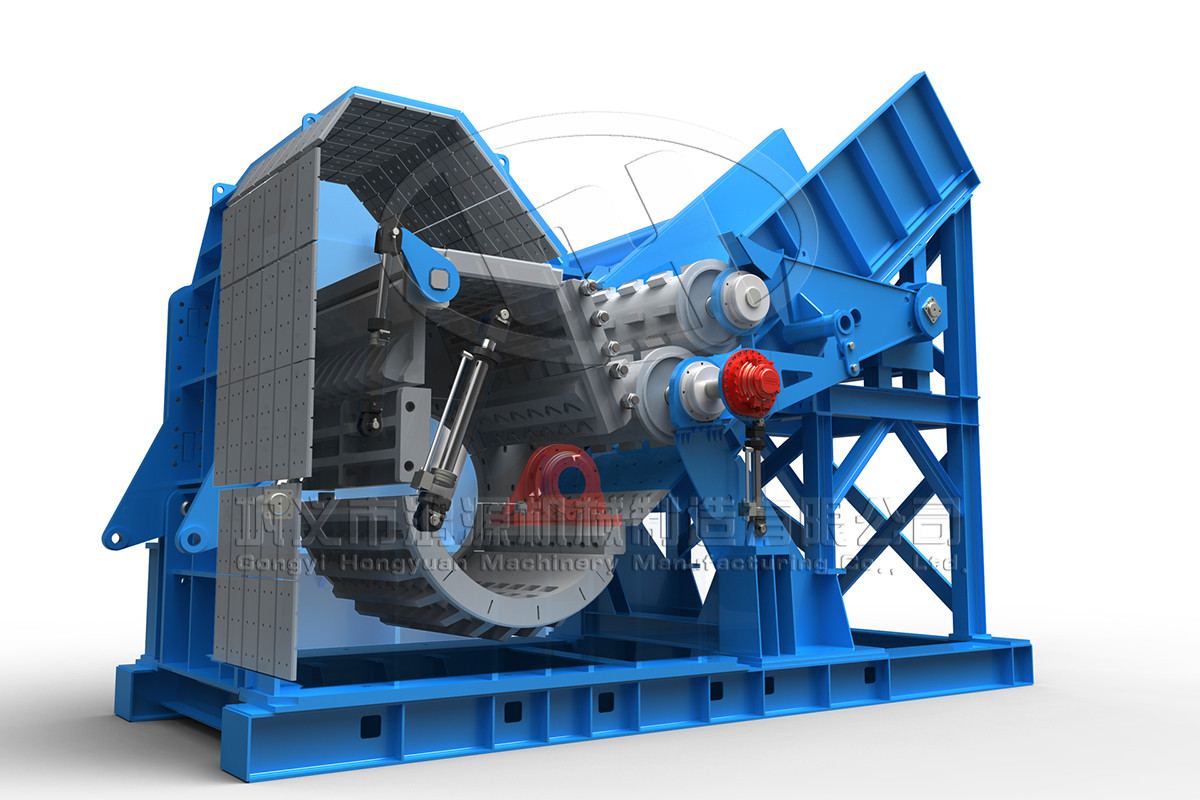

The car crusher is fed into the equipment sliding silo through the equipment configuration of the loading conveyor. The material is evenly fed into the main cavity of the equipment through the forced pressing roller extrusion and the material of the material. During the rotation process, the material is crushed by the hammerhead, and the broken car shell is crushed into spherical metal particles by the roller press at high speed in the machine cavity, and the waste standard is discarded under repeated impact. The metal is discharged into the machine cavity through the bottom screen, and the discharged raw materials are sent to the sorting system through the discharge conveyance to sort the impurities, scrap iron, scrap copper and waste in the scrap metal to obtain high-quality raw materials of high composition. For regenerative metallurgical processing. In addition to the above facilities, the equipment is equipped with soundproof rooms and dust removal systems to reduce noise and pollution.

| model | power | Application range | Rotating speed | Processing capacity(t/h) | Dimensions(mm) | weight(t) |

| 800PSJ-C | 37-55 | Cans, thin iron, light metal | 1250 | 0.7-1 | 3800*1600*1800 | 3.2 |

| 1000PSJ-C | 45-75 | Small metal packing, cans, scrap metal | 1250 | 0.8-1.5 | 2560*1800*2200 | 7.6 |

| 1300PSJ-C | 90-150 | Scrap metal blocks such as bicycles and motorcycles | 860 | 2-4 | 4000*3500*3200 | 11.5-26 |

| 1600PSJ-C | 200-280 | Scrap metal parts such as automobile cutting parts and paint buckets | 750 | 4-6 | 4800*4000*3800 | 16.6-35 |

| 1800PSJ-C | 220-450 | Scrapped large scrap metal blocks | 650 | 6-10 | 4800*4100*4000 | 32-48 |

| 2000PSJ-C | 315-630 | Scrapped large scrap metal blocks | 650 | 8-12 | 5000*4500*4300 | 35-65 |

| 2200PSJ-C | 500-900 | Scrapped large scrap metal blocks | 650 | 15-20 | 5000*4500*4300 | 35-65 |

| 2400PSJ-C | 1250-2250 | Large metal packing, car shell | 650 | 20-45 | 6300*4800*4500 | 85-120 |

| 2800PSJ-C | 1600-3300 | Various scrap metal | 650 | 70-100 | 6400*5200*4800 | 145-230 |

| 3000PSJ-C | 3300-4400 | Various scrap metal | 650 | 110-140 | 8500*7200*5500 | 280-760 |

Copyright © 2099 Walle Recycle All Rights Reserved.