The new automobile crushing production line is a large-scale automobile shell dismantling and crushi

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

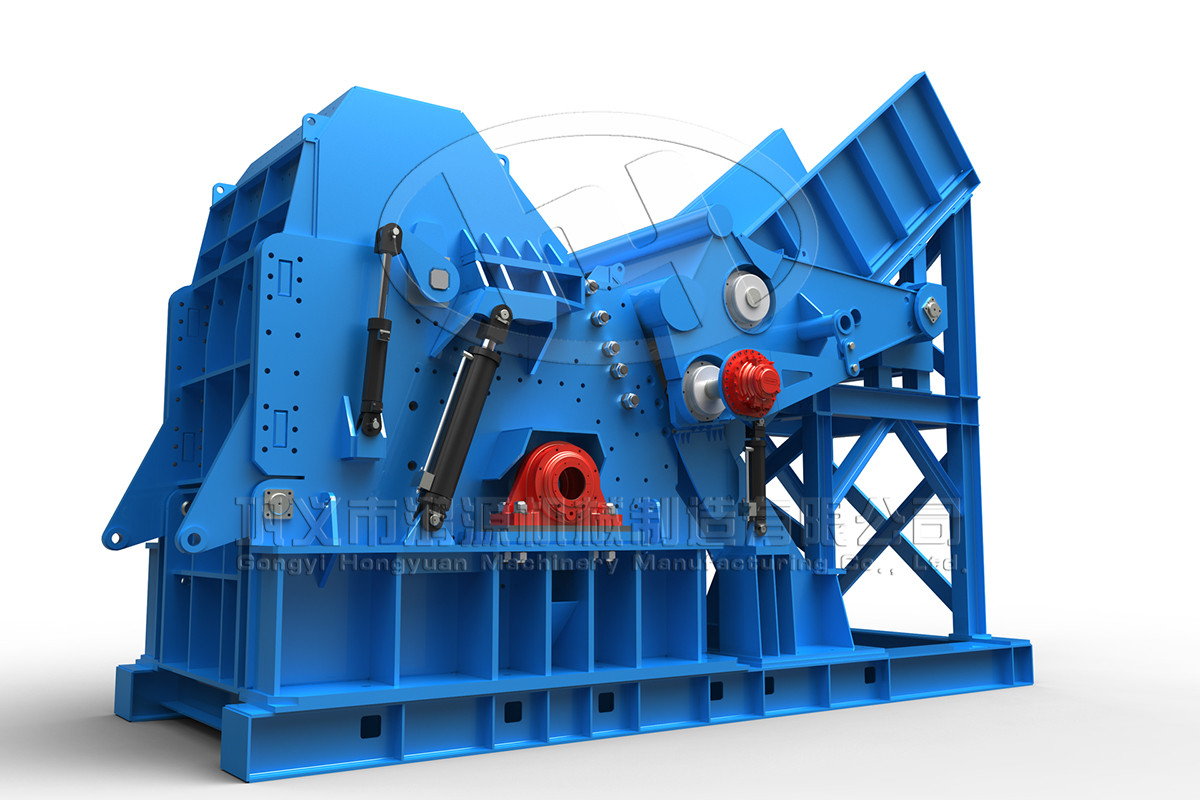

The new automobile crushing production line is a large-scale automobile shell dismantling and crushing processing equipment developed by Gongyi Hongyuan Machinery combined with the advanced experience of metal crushing at home and abroad. This production line can save more than 20% of the cost investment compared with the old production line, and in the whole production line. The configuration basically realizes the requirements of fully automated pulverizing operation, and has the advantages of low labor cost, strong equipment running continuity, high efficiency of crushing and disassembling, and high quality of scrap metal smelting.

Hongyuan

Machinery 1600 scrap crushing Thai production line, the main components of the production line are: metal shredder, feeding machine, vertical metal shredder, magnetic separation separator, integrated power distribution cabinet, dust collector and other equipment, The production line is a 12-ton production line per hour, which can be used for medium-sized metal garbage recycling and disposal units and automobile waste dismantling units. For customers with higher overall demand, you can choose 30 tons per hour production line, 40 tons per hour production line, 60 tons per hour production line, 80 tons per hour production line, 100 tons per hour production line or customize to meet relevant equipment processing and operation standards. (Note: For companies with high qualifications and relevant state subsidies, our company can provide higher configuration and special design. For domestic small and medium-sized customers, you can also purchase our company’s built-in equipment standards.)

Performance characteristics

1.The overall crushing process of the large automobile casing reduces the labor cost in the overall cutting process and reduces the operation intensity.

2.High degree of automation, overall streamline operation, one-time coarse and fine crushing of the car shell to meet the requirements of modern industry.

3. Low noise, shorter time and less noise than traditional crushing process.

4.Energy saving and environmental protection, supporting integrated dust removal device, the overall streamline operation is more energy efficient.

Institution

Feeding and conveying mechanism: Mainly to realize the transportation of waste metal into and out of the equipment by chain conveyor and belt

transportation.

Coarse crushing mechanism: It mainly undertakes the overall cutting and coarse crushing of large scrap metal such as automobile shell and packing

material to provide pre-order process conditions for achieving fine crushing.

Fine crushing mechanism: It mainly undertakes the fine-breaking processing of scrap metal after shearing and shredding to realize the separation of metal surface paint and debris and the smashing operation of scrap metal.

Magnetic separation and separation mechanism: Separation of waste magnetic separation material and non-magnetic material by magnetic separation, on the basis of which vibration and gas flotation mechanism are used to separate and sort materials such as plastic and wood.

| model | power | Application range | Rotating speed | Processing capacity(t/h) | Dimensions(mm) | weight(t) |

| 800PSJ-C | 37-55 | Cans, thin iron, light metal | 1250 | 0.7-1 | 3800*1600*1800 | 3.2 |

| 1000PSJ-C | 45-75 | Small metal packing, cans, scrap metal | 1250 | 0.8-1.5 | 2560*1800*2200 | 7.6 |

| 1300PSJ-C | 90-150 | Scrap metal blocks such as bicycles and motorcycles | 860 | 2-4 | 4000*3500*3200 | 11.5-26 |

| 1600PSJ-C | 200-280 | Scrap metal parts such as automobile cutting parts and paint buckets | 750 | 4-6 | 4800*4000*3800 | 16.6-35 |

| 1800PSJ-C | 220-450 | Scrapped large scrap metal blocks | 650 | 6-10 | 4800*4100*4000 | 32-48 |

| 2000PSJ-C | 315-630 | Scrapped large scrap metal blocks | 650 | 8-12 | 5000*4500*4300 | 35-65 |

| 2200PSJ-C | 500-900 | Scrapped large scrap metal blocks | 650 | 15-20 | 5000*4500*4300 | 35-65 |

| 2400PSJ-C | 1250-2250 | Large metal packing, car shell | 650 | 20-45 | 6300*4800*4500 | 85-120 |

| 2800PSJ-C | 1600-3300 | Various scrap metal | 650 | 70-100 | 6400*5200*4800 | 145-230 |

| 3000PSJ-C | 3300-4400 | Various scrap metal | 650 | 110-140 | 8500*7200*5500 | 280-760 |

Copyright © 2099 Walle Recycle All Rights Reserved.