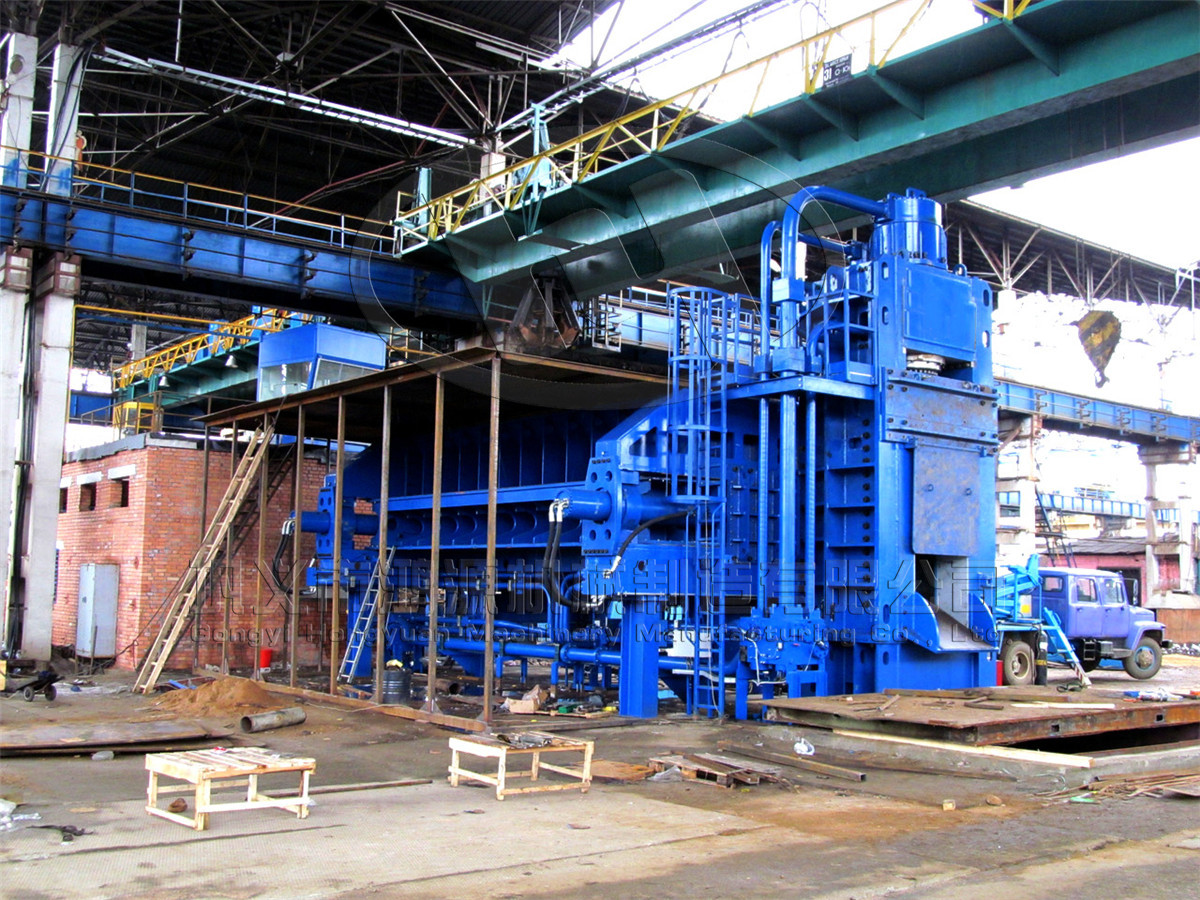

The metal shearing machine is easy to control by buttons and pedals. The gantry shear has a back p

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

The

metal shearing machine is easy to control by buttons and pedals. The

gantry shear has a back panel fixed width device, and the double

cylinder uses the mechanical balance principle to make the shearing

process of the nickel plate and the electrolytic copper plate more

regular and stable.

Features

(1)

This machine adopts hydraulic drive, which has the characteristics of

small volume, light weight, small motion inertia, low noise, smooth

motion, flexible operation and large shear section compared with

mechanical transmission shearing machine.

(2)

It adopts integrated liquid-electric control, can perform single-time,

continuous action conversion, is simple and convenient to use, can be

stopped and operated at any working position, and is easy to realize

overload protection.

(3)

It can be used in a wide range of applications, both as processing

equipment for metal recycling and processing units, as a metal cutting

equipment for furnace processing and mechanical construction in the

foundry of the factory.

(4) Increased production efficiency.

The

shearing machine has large shearing force and long cutting edge, and is

suitable for cold cutting of various sections of profile steel (such as

round steel, square steel, channel steel, I-beam, steel plate, steel

pipe, etc.) and various scrap metal structural parts. .

The

whole machine has a compact structure and the steel body is welded into

a box-shaped structure, and the mechanical properties are stable. The

shearing cylinder is connected by ball joints, which improves the

stability and life of the cylinder, and increases the capacity of the

whole machine. It

adopts electro-hydraulic control, simple operation, and can realize

automatic circulation of jog and linkage. It is one of the ideal

equipment for metal recycling industry and foundry furnace processing.

|

model |

Shear force(TON) |

Pressing force(TON) |

Knife length(MM) |

Dehisce(MM) |

Cuts per minute(T/S)) |

Mainly cut material size(MM) |

Total machine power(KW) |

Operation method |

|

QSZ43-63 |

63 |

16 |

600 |

280 |

9-16 |

30X30 Ø35 |

7.5 |

Manual feeding or linkage |

|

QSZ4-100 |

100 |

16 |

600 |

280 |

9-16 |

40X40 Ø45 |

11 |

|

|

QSZ43-120 |

120 |

20 |

600 |

280 |

9-16 |

45X45 Ø50 |

15 |

|

|

QSZ43-160 |

160 |

25 |

700 |

320 |

9-16 |

55X55 Ø63 |

18.5 |

|

|

QSZ43-200 |

200 |

25 |

800 |

380 |

9-16 |

65X65 Ø75 |

22 |

|

|

QSZ43-250 |

250 |

26 |

1000 |

480 |

9-16 |

70X70 Ø80 |

30 |

|

|

QSZ43-315 |

315 |

42 |

1200 |

520 |

8-16 |

80X80 Ø90 |

37 |

|

|

QSZ43-400 |

400 |

42 |

1500 |

700 |

8-16 |

90X90 Ø100 |

44 |

|

|

QSZ43-500 |

500 |

42 |

1800 |

900 |

8-16 |

100X100 Ø110 |

44 |

Copyright © 2099 Walle Recycle All Rights Reserved.