Waste paper shredder is a professional shredder crushing equipment. It can be used in the pape

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

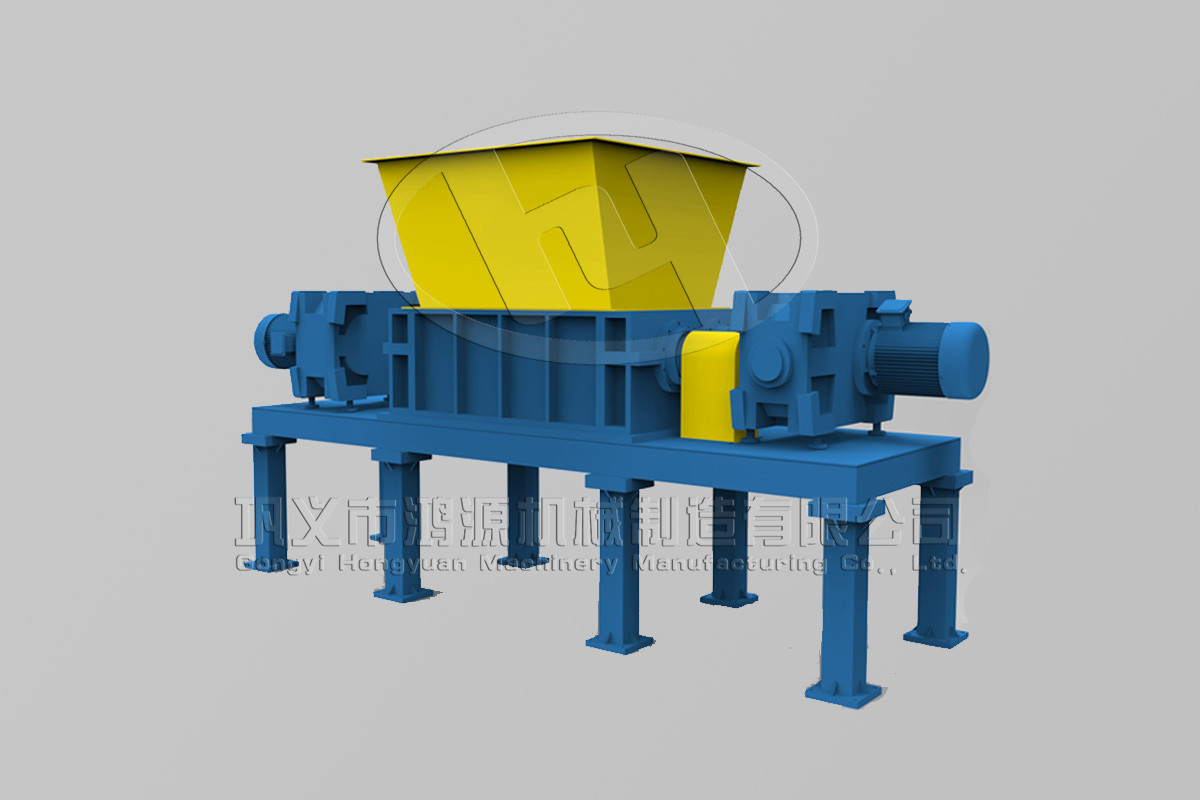

Waste paper shredder is a professional shredder crushing equipment. It can be used in the paper mill for the crushing and sorting of the mixture of rake material, plastic film, waste paper box and iron wire in the paper mill. Combustion and carbon processing. Hongyuan Machinery can provide you with the overall production line planning in the waste paper treatment of paper mills, and solve the problem of difficult processing and pollution of paper mill waste.

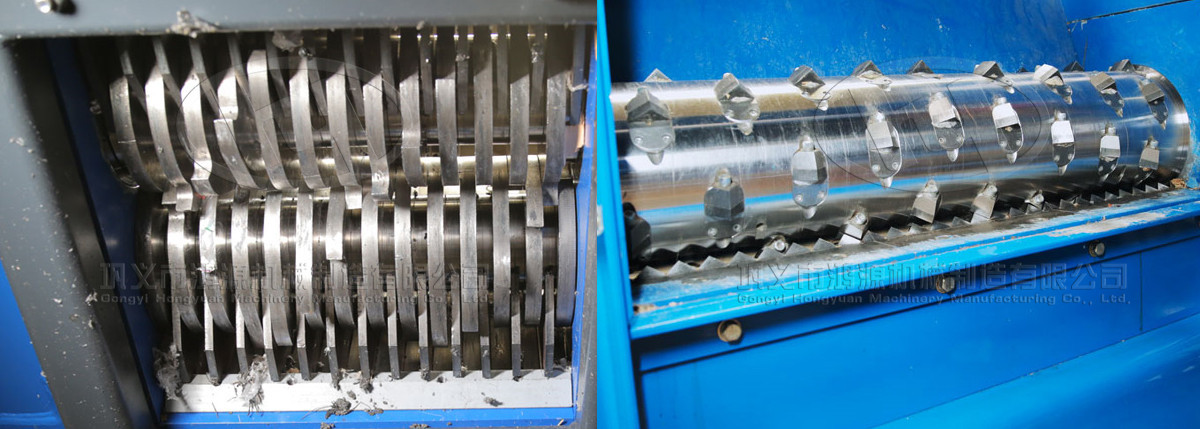

The production line consists of five stages of process equipment: two-axis crusher, conveying equipment, dryer, continuous carbonization equipment, and carbon powder molding equipment. The specific output of the equipment can be selected according to customer requirements. The power part of the equipment is driven by planetary gear reducer. The blade is made of high-strength alloy steel. It has strong wear resistance and high strength. Speed running, tearing, squeezing, biting and other functions. The electrical part is controlled by PLC and has the functions of automatic detection of overload protection. The application of this machine is produced in the demand for strong equipment in the carton packaging industry and the paper industry. The performance of the paper industry crushing equipment is more prominent than that of the crushing equipment. The processing material range is not affected by the glue and metal impurities in the paper. High output and wide application range.

Institutional principle

The waste paper shredder is similar in operation to the double-shaft shredder. It uses two rotors with a shredder blade to rotate relative to each other in the machine cavity to adopt the principle of contracting the two axes to enter the machine cavity. The material is extruded. Because the special design of the blade enters the angle between the two axes, the material is fixed by the edge of the blade to further create the condition for the contraction of the angle. After the material is forced to reach the yield strength of the material, the material begins to break between the blades, thereby completing. Shredded effect.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.