The metal shredder is also called double-shaft crusher and double-axis metal crusher. This mac

7 * 24 hour free hotline

+86 1879029661260 seconds response

Reply within 30 minutes

24-hour free plan

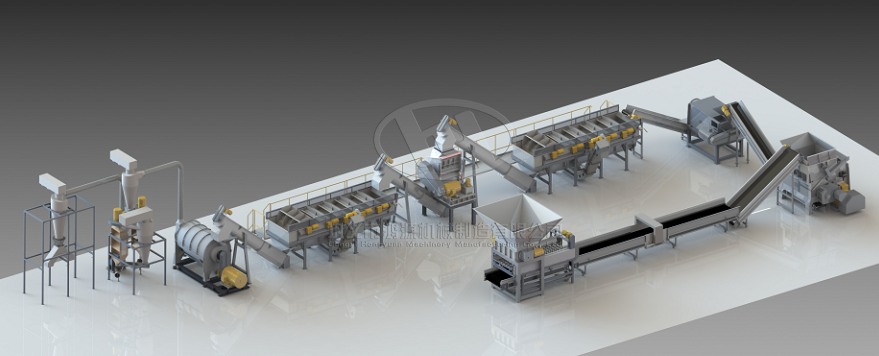

The metal shredder is also called double-shaft crusher and double-axis metal crusher. This machine is a new type of shear crusher researched and developed by Hongyuan Machinery according to market demand. It is mainly used as metal coarse crushing equipment. Large-scale waste air materials such as scrap car shells, color steel tiles, paint buckets, etc. are crushed and processed. The processed materials are in the form of granules or sheets according to the thickness and material type. The machine has low noise and dust relative to the metal pulverizer. Less, more applicability, and greater crushing ratio.

In terms of equipment suitability, the metal shredder is mainly used as a metal shredder in front of the coarse crushing equipment for pretreating large metal that cannot be broken by the metal shredder. The metal shredder is mainly composed of a shredder blade set, a carrying case, a box bracket, a feeding system, a power system and an electrical control system. The unique power protection mechanism of the machine in the process of crushing large scrap metal It can effectively prevent equipment damage caused by overloading equipment.

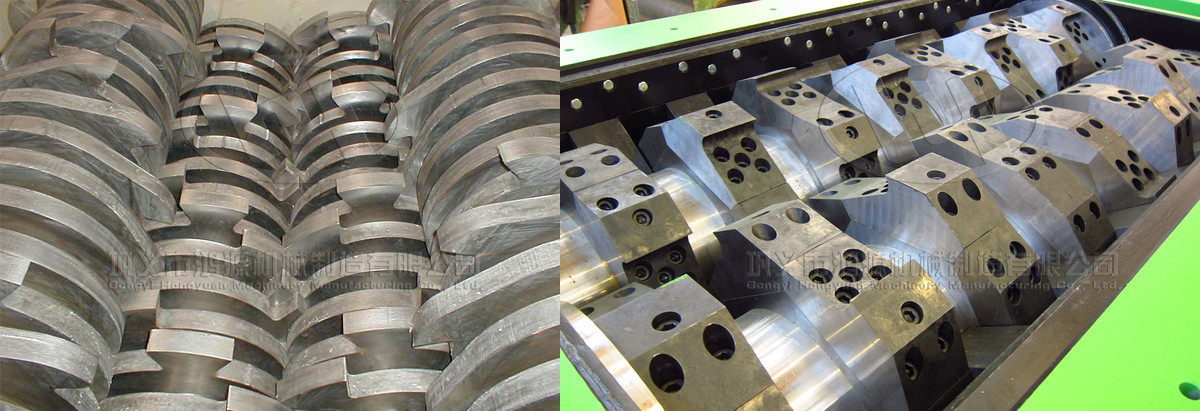

Structural principle

The metal shredder is commonly used in the design of equipment production. There are two-axis metal shredders and four-axis metal shredders. During the working process, the machine transmits the power to the main shaft through the reducer connected to the motor. The scrap metal blade fixed to the main shaft is pulled under the traction to clamp the scrap metal entering the metal shredder cavity. During the continuous pressing process of the blade clamping position, the material is drawn into the two-axis slit and passes through the two-axis. The tearing effect causes the material to achieve the crushing effect. The crushed material is usually stripped or flaked and filtered from the bottom of the device and transported through the conveyor belt to the other material for centralized treatment or direct collection.

|

Model

|

Power(kw) |

Rotating speed(r/min) |

Yield(t) |

Number of cutters

|

Cutter diameter(mm) |

Reducer

|

Length, width and height(m) |

|---|---|---|---|---|---|---|---|

|

400SQ

|

4-11*2

|

12-25

|

0.5-1

|

Depending on the thickness of the cutter Y=L/T

Y Number of cutters L Model T Cutter thickness |

φ200

|

250*2

|

1.8*1.5*1.6

|

|

600SQ

|

4-15*2

|

10-24

|

2-3

|

φ200

|

350*2

|

2.6*2*1.9

|

|

|

800SQ

|

4-22*2

|

10-24

|

3-4

|

φ360

|

500*2

|

2.8*2*1.9

|

|

|

1000SQ

|

6-30*2

|

8-22

|

4-5

|

φ400

|

600*2

|

3*2*1.9

|

|

|

1200SQ

|

6-37*2

|

8-22

|

6-10

|

φ450

|

650*2

|

3.4*2.2*2.2

|

|

|

1400SQ

|

6-45*2

|

8-24

|

8-12

|

φ520

|

750*2

|

4*3*2.4

|

|

|

1600SQ

|

6-55*2

|

8-24

|

10-18

|

φ560

|

750*2

|

5*3*2.4

|

|

|

1900SQ

|

6-75*2

|

6-20

|

14-22

|

φ650

|

800*2

|

6*3.5*2.5

|

|

|

2200SQ

|

6-110*2

|

6-20

|

18-26

|

φ750

|

850*2

|

7.5*4*4.5

|

Copyright © 2099 Walle Recycle All Rights Reserved.